1. How to do when the goods broken? 100% in time after-sales guaranteed! (Refund or Resent goods can be discussed based on the damaged quantity.) 2. Shipping EXW is normally; By sea or air can be selected. 3. Payment term Bank transfer Need more pls contact 4.Quick response service 8:30-17:30 within 10 min get response; We will get back to you within 2 hours when not in office; Sleeping time is saving energy For give you more effective feedback, pls leave message, we will get back to you when wake up!Prevent the particles that can generate from the bevel or angled edges and the back surface while wafers are transported or being in contact with End Effector / Handling Arm. For the guides, adopted a soft material that does not damage the wafer. Thinning is possible with ST.CERA's built-in vacuum channel technology that does not use adhesives. Possible to make mounting holes and to change the length and width of the base where the End Effector / Handling Arm is mounted on the robot. Mounting sensors, screws and brackets is available as an option. Designed to be used in atmosphere.

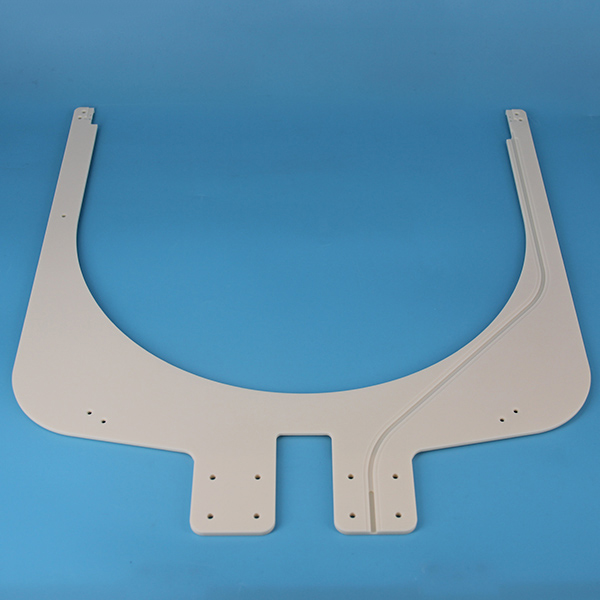

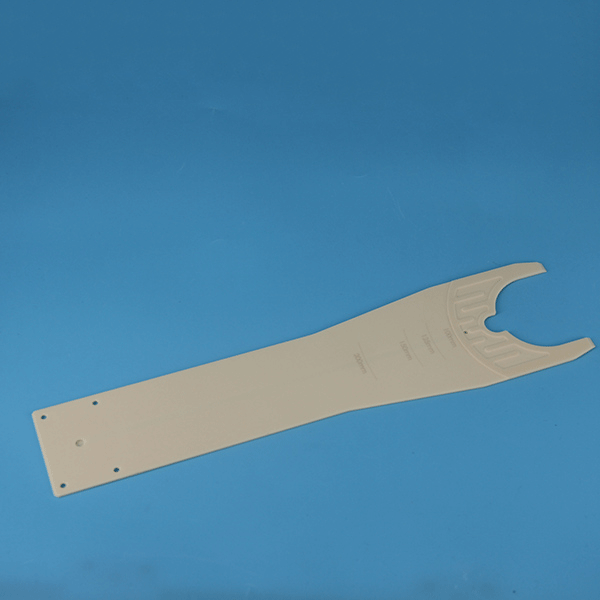

1. How to do when the goods broken? 100% in time after-sales guaranteed! (Refund or Resent goods can be discussed based on the damaged quantity.) 2. Shipping EXW is normally; By sea or air can be selected. 3. Payment term Bank transfer Need more pls contact 4.Quick response service 8:30-17:30 within 10 min get response; We will get back to you within 2 hours when not in office; Sleeping time is saving energy For give you more effective feedback, pls leave message, we will get back to you when wake up!Prevent the particles that can generate from the bevel or angled edges and the back surface while wafers are transported or being in contact with End Effector / Handling Arm. For the guides, adopted a soft material that does not damage the wafer. Thinning is possible with ST.CERA's built-in vacuum channel technology that does not use adhesives. Possible to make mounting holes and to change the length and width of the base where the End Effector / Handling Arm is mounted on the robot. Mounting sensors, screws and brackets is available as an option. Designed to be used in atmosphere.ST.CERA Customized Alumina Ceramic gripping end effector

ST.CERA Customized Alumina Ceramic gripping end effector - Quality factory direct ceramic end effectors for precision gripping. Contact us for custom solutions.

Request a QuotePRODUCTS DETAILS

1. How to do when the goods broken? 100% in time after-sales guaranteed! (Refund or Resent goods can be discussed based on the damaged quantity.) 2. Shipping EXW is normally; By sea or air can be selected. 3. Payment term Bank transfer Need more pls contact 4.Quick response service 8:30-17:30 within 10 min get response; We will get back to you within 2 hours when not in office; Sleeping time is saving energy For give you more effective feedback, pls leave message, we will get back to you when wake up!Prevent the particles that can generate from the bevel or angled edges and the back surface while wafers are transported or being in contact with End Effector / Handling Arm. For the guides, adopted a soft material that does not damage the wafer. Thinning is possible with ST.CERA's built-in vacuum channel technology that does not use adhesives. Possible to make mounting holes and to change the length and width of the base where the End Effector / Handling Arm is mounted on the robot. Mounting sensors, screws and brackets is available as an option. Designed to be used in atmosphere.

1. How to do when the goods broken? 100% in time after-sales guaranteed! (Refund or Resent goods can be discussed based on the damaged quantity.) 2. Shipping EXW is normally; By sea or air can be selected. 3. Payment term Bank transfer Need more pls contact 4.Quick response service 8:30-17:30 within 10 min get response; We will get back to you within 2 hours when not in office; Sleeping time is saving energy For give you more effective feedback, pls leave message, we will get back to you when wake up!Prevent the particles that can generate from the bevel or angled edges and the back surface while wafers are transported or being in contact with End Effector / Handling Arm. For the guides, adopted a soft material that does not damage the wafer. Thinning is possible with ST.CERA's built-in vacuum channel technology that does not use adhesives. Possible to make mounting holes and to change the length and width of the base where the End Effector / Handling Arm is mounted on the robot. Mounting sensors, screws and brackets is available as an option. Designed to be used in atmosphere.Hot Products

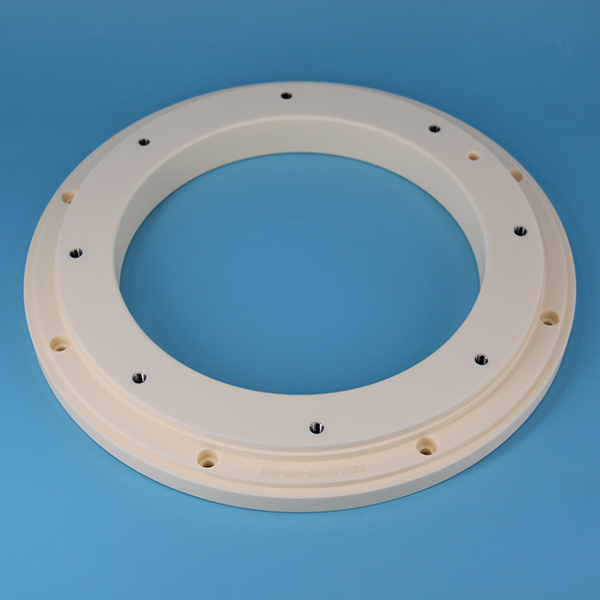

ST.CERA Customized semiconductor Ceramic focus ring

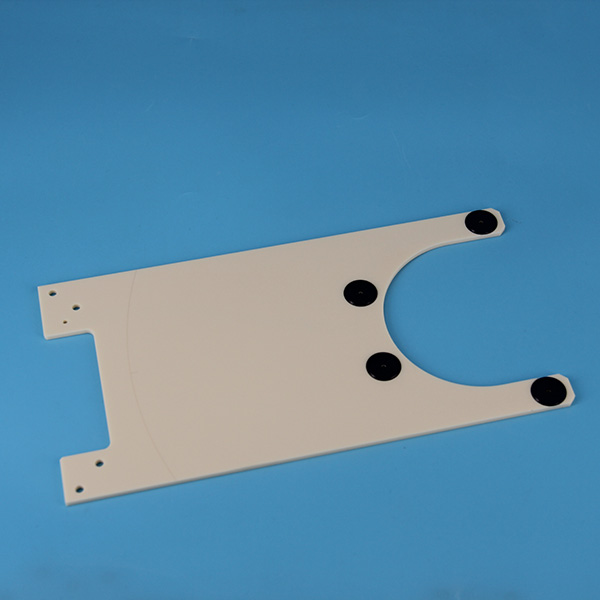

ST.CERA Customized 99.5% Alumina Ceramic Loader Arm

ST.CERA Customized 99.5% Alumina Ceramic rod

ST.CERA Customized 99.5% Alumina Ceramic tube

ST.CERA Customized Alumina Ceramic Bernoulli end effector

ST.CERA Customized 99.5% Alumina Ceramic parts

ST.CERA Customized semiconductor Ceramic bushing

ST.CERA Customized Zirconia Ceramic tube

ST.CERA Customized Alumina Ceramic vacuum end effector

ST.CERA Customized 99.5% zirconia Ceramic rod ceramic pin

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours